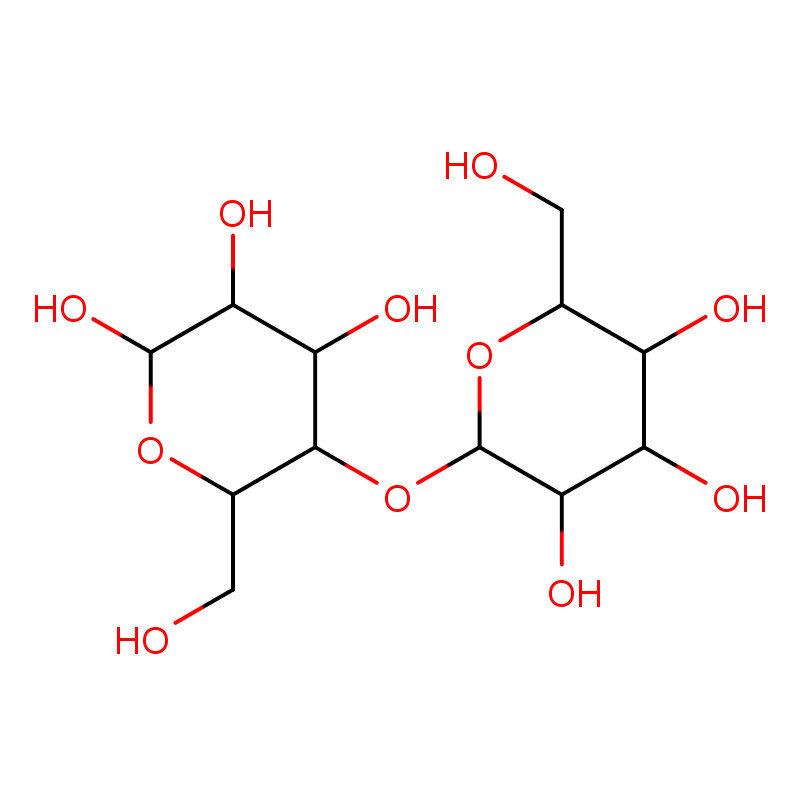

In 1833, the French chemist Anselme Perrin firstly isolated cellulose, a polysaccharide composed of long-chain glucose molecules, from wood.

Cellulose is one of the most abundant renewable resources on Earth, mainly found in plant cell walls, and its microscopic microfibril provides strength and rigidity to plant cell walls, making cellulose an ideal material for manufacturing packaging.

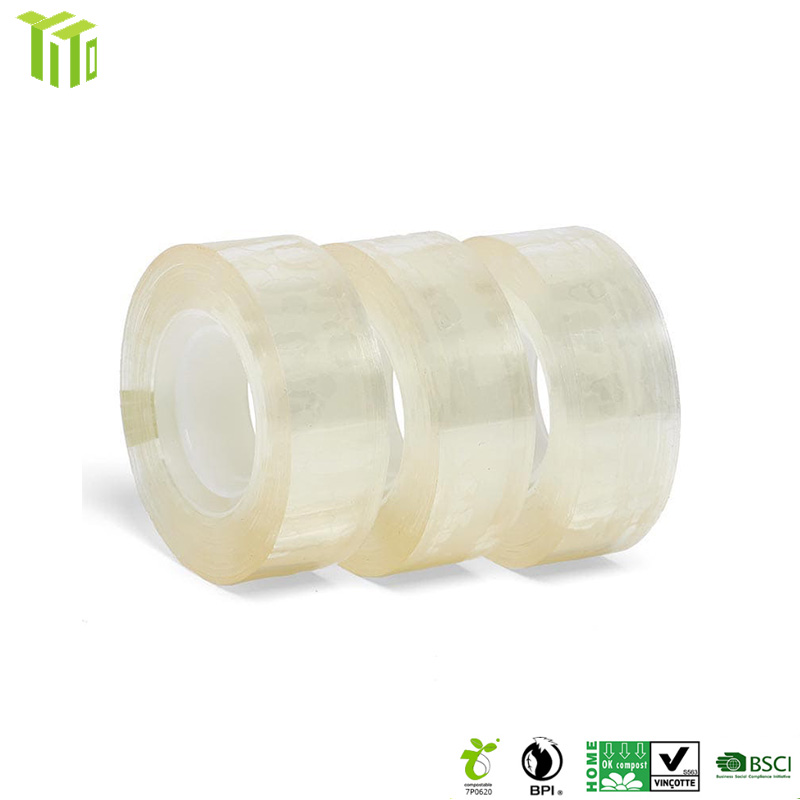

Cellulose can be processed into a thin and transparent degradable film: cellophane, which is widely used in the field of environmentally friendly and sustainable packaging solutions.

Let's delve into the world of Cellulose and Cellophane today together.

1. How is cellophane made?

-

Extraction of cellulose:

Cellulose is extracted from cotton, wood or other sustainably harvested natural sources to make a white dissolved pulp with a cellulose content of 92-98%.

-

Mercerization:

Elevates the ordinary to the extraordinary, turning a simple message into a treasured keepsake.

- Incorporation of carbon disulfide:

Carbon disulfide is applied to mercerized pulp to form a solution called cellulose xanthate or viscose.

- Film forming:

The solution is added to a coagulation bath with a mixture of sodium sulfate and dilute sulfuric acid to form a cellulose film.

- Post-treatment:

The cellulose membrane is washed three times. The sulfur is first removed, then the film is bleached, and finally glycerin is added to improve durability.

The final biodegradable cellophane is completed, after coating, printing and other processing, it can be used in clothing, food, jewelry, electronics, home, gifts, greeting cards and other packaging.

2. What are the green benefits of cellulose packaging bag application?

It is estimated that 320 million tons of plastic are produced globally each year, of which about 8 million tons of plastic waste enters the ocean, and more than 100,000 Marine animals die each year from eating plastic or becoming entangled in plastic. In addition, when plastic breaks down, it creates microplastic particles that are able to penetrate the food chain and eventually affect humans, potentially increasing the risk of heart attack, stroke or death.

Therefore, degradable packaging materials - a good substitute for plastic packaging bags in cellulose film packaging rooms, is of great significance for protecting the environment and human health.

HuiZhou YITO Packaging Co., Ltd. has been deeply engaged in environmental protection and biodegradable industry for 7 years, specializing in providing biodegradable packaging materials.

In addition, what are the environmental benefits of cellulose film packaging bags?

-

Safe and sustainable:

The raw materials of cellophane packaging bags come from bio-based renewable resources, such as cotton, wood, etc., and the ingredients are safe, reducing the long-term burden on the environment

-

Biodegradable:

Cellophane packaging bags can be biodegradable. Tests have shown that uncoated cellulose packaging biodegrades in 28-60 days, while coated products biodegrade in 80-120 days; Uncoated cellophane bags degrade in water within 10 days; If coated, it will take about a month.

-

Home compostable:

Without industrial machinery and equipment, cellophane can be safely placed in the compost pile at home.

3. What are the advantages of cellophane bags?

High transparency:

Cellophane paper bag is a class of paper, compared with other paper classes, cellophane has high transparency.

High safety :

Cellophane bags have non-toxic and tasteless characteristics.

High transparency and gloss :

Cellophane paper bag surface bright.

Strong tensile and scalability:

The horizontal and longitudinal tensile capacity of the cellophane bag is good.

Printability

The surface of the cellophane bag is smooth, the printing adaptability is good, and a variety of patterns and text can be printed to increase the beauty of the product and brand recognition.

High temperature resistance:

Cellophane bags can be used in high temperature environments.

Anti-static and dust-proof :

The cellophane bag is not easy to produce static electricity, so it is not easy to absorb dust, and keep the packaging clean and tidy

Moisture and oil resistantt - Biodegradable cellophane bags are resistant to moisture and water vapor, as well as oil and fat, making them an excellent choice for products.

4. FAQs about Cellulose Film Packaging

FAQ 1: Are cellulose film and pulp paper packaging suitable for food products?

Yes, both cellulose film and pulp paper are commonly used for food packaging due to their natural composition and barrier properties.

They can help maintain the freshness of food products while being safe for direct contact with food.

YITO specializes in providing a variety of environmentally friendly packaging materials and is a supplier you can trust.

FAQ 2: Can customized packaging services be provided?

Yes, we can provide customized packaging services. We understand that each customer's products and needs are unique. Whether you need specific sizes, shapes, printing patterns or other special requirements, we have a professional team to serve you.

First, you can communicate your specific needs with our sales representatives, and we will provide a design plan and quotation according to your requirements. During the design process, we will work closely with you to ensure that the packaging design conforms to your brand image and product characteristics.

Then, our production team will produce according to the customized plan, strictly control the quality and production progress, and ensure the timely delivery of satisfactory customized products. We are committed to providing you with personalized, high-quality packaging solutions to meet your different needs.

FAQ 3: How is the product price determined?

YITO has been dedicated to a variety of visual effect packaging materials for many years, earning trust and reliability in the industry.

FAQ 4: Can Cellulose Film be customized for different packaging needs?

Absolutely!Cellulose Film can be customized in various ways, including different thicknesses, colors, and designs, to meet the specific requirements of different packaging and branding strategies, making it a versatile choice for a wide range of packaging needs.

Cellulose film is the trend of package material. Follow us and we will provide you with more details products and news about it!

Related Products

Post time: Oct-11-2024