Best Cellophane Manufacturer,factory In China

Double-sided heat-sealing cellophane film --TDS

Both average gauge and yield are controlled to better than ± 5% of the nominal values. The crossfilm thickness profile or variation will not exceed ± 3% of the average gauge.

Cellophane Glitter

Glitter, also known as shimmer pieces or shimmer powder, is made from electroplated and coated materials of different thicknesses such as PET, PVC, and OPP metallic aluminum film, which are precisely cut.

Glitter particle sizes can range from 0.004mm to 3.0mm. The most environmentally friendly material is PET and Cellophane.

Shapes include square, hexagonal, rectangular, and rhombic etc. Color series of glitter include laser silver, laser gold, laser colors (including red, blue, green, purple, peach pink, black), silver, gold, colors (red, blue, green, purple, peach pink, black), and iridescent series.

Each color series has an added protective layer on the surface, making them bright in color and resistant to mild corrosion by climate, temperature, and chemicals.

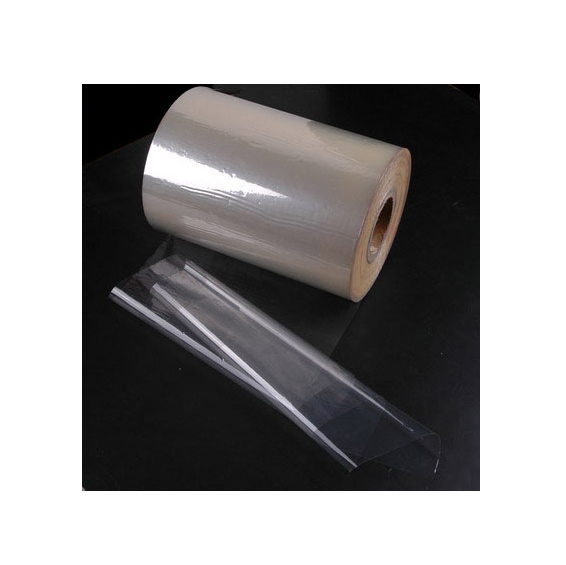

transparent roll cellophane film

Color: Customize

Shape: Hexagon, round sequin,five-pointed star, Moon, butterfly,etc

Usage: Kids toys, DIY, apply,spray, pastes, etc

Size: 0.004mm-3mm

Application: party,wedding,face,body,hair,lips,etc

Logo Customization

Material: Plant Fiber

Material Description

Typical physical performance parameters

|

Item |

Unit |

Test |

Test method |

||||||

|

Material |

- |

CAF |

- |

||||||

|

Thickness |

micron |

19.3 |

22.1 |

24.2 |

26.2 |

31 |

34.5 |

41.4 |

Thickness meter |

|

g/weight |

g/m2 |

28 |

31.9 |

35 |

38 |

45 |

50 |

59.9 |

- |

|

Transmittance |

units |

102 |

ASTMD 2457 |

||||||

|

Heat sealing temperature |

℃ |

120-130 |

- |

||||||

|

Heat sealing strength |

g(f)/37mm |

300 |

120℃ 0.07mpa/1s |

||||||

|

Surface Tension |

dyne |

36-40 |

Corona pen |

||||||

|

Permeate water vapor |

g/m2.24h |

35 |

ASTME96 |

||||||

|

Oxygen permeable |

cc/m2.24h |

5 |

ASTMF1927 |

||||||

|

Roll Max Width |

mm |

1000 |

- |

||||||

|

Roll Length |

m |

4000 |

- |

||||||

Advantage of Cellophane

Beautiful sparkle, clarity and gloss

Offers a tight package that will extend the shelf life of your products while protecting them from dust, oil and moisture.

Tight, crisp, even shrink in all directions.

Provides consistent sealing and shrinking at a broader range of temperatures.

Performs reliably even in less-than-ideal operating conditions.

Compatible with all sealing systems including manual, semi-automated and automated.

Yields cleaner, stronger seals eliminating blowouts.

Features of biodegradable glitter

Precautions

Packing Requirement

Applications of Cellophane Glitter

YITO's glitter is widely used in various fields, including biodegradable cosmetic glitter, biodegradable glitter for candles, biodegradable face glitter, biodegradable glitter for crafts, biodegradable hair glitter, biodegradable glitter for soap, biodegradable glitter spray, biodegradable glitter confetti, biodegradable glitter for bath bombs, etc.

Its characteristics lie in enhancing the visual effect of products, making the decorative parts concave and convex with more three-dimensional sense, while its highly reflective makes the decorations more vivid and eye-catching.

Technical Data

As a cellophane film manufacturer, we suggest you that when you buy the cellophane film, there are many different features to consider like the size, thickness and color. For this reason, is recommended that you discuss your specifications and requirements with an experienced manufacturer, ensuring that you receive the very best value. Common thickness is 20μ, if you have other requirement, please tell us, as a cellophane film manufacturer, we can custom according to your requirement.

| Name | cellophane |

| Density | 1.4-1.55g/cm3 |

| Common thickness | 20μ |

| Specification | 710一1020mm |

| Moisture permeability | Increase with increasing humidity |

| Oxygen permeability | Change with humidity |

Frequently Asked Questions

cellophane, a thin film of regenerated cellulose, usually transparent, employed primarily as a packaging material. For many years after World War I, cellophane was the only flexible, transparent plastic film available for use in such common items as food wrap and adhesive tape.

Cellophane is made from a rather complex process. Cellulose from wood or other sources is dissolved in alkali and carbon disulfide to form a viscose solution. The viscose is extruded through a slit into a bath of sulfuric acid and sodium sulfate to reconvert the viscose into cellulose.

Plastic wrap—like the sheer cover used to preserve leftovers—is clingy and feels more like a film. Cellophane, on the other hand, is thicker and markedly stiffer with no cling abilities.

Cellophane has been around for more than 100 years but these days, the product that most people call Cellophane is actually polypropylene. Polypropylene is a thermoplastic polymer, discovered by accident in 1951, and has since become the world's second most widely manufactured synthetic plastic.

Cellophane has some properties similar to plastic, making it a more attractive option for brands wanting to go plastic-free. In terms of disposal cellophane is certainly better than plastic, however it is not suitable for all applications. Cellophane cannot be recycled, and it isn't 100% waterproof.

Cellophane is a thin, transparent sheet made of regenerated cellulose. Its low permeability to air, oils, greases, bacteria, and liquid water makes it useful for food packaging.

Cellophane membranes are regenerated transparent cellulose membranes of high hydrophilicity, good mechanical properties, and biodegradability, biocompatibility, and gas barrier characters. The crystallinity and porosity of the membranes have been controlled through the regeneration conditions over the last decades.

If you look through green glass, everything appears green. Green cellophane will only allow green light to pass through it. The cellophane absorbs other colours of light. For example, green light will not pass through red cellophane.

Plastic wrap—like the sheer cover used to preserve leftovers—is clingy and feels more like a film. Cellophane, on the other hand, is thicker and markedly stiffer with no cling abilities.

While both are used for food packaging, the types of food cellophane and plastic wrap are used on are different.

You’ve likely seen cellophane wrapped around candies, baked goods, and even encasing boxes of teas. The packaging has low moisture and oxygen permeability making it great for keeping things fresh. It’s much easier to tear and remove than plastic wrap.

As for plastic wrap, it can easily give food a tight seal thanks to its clingy nature, and because it’s malleable, it can fit a variety of items. Unlike cellophane, it’s much harder to tear and remove from products.

Then, there’s what they are made from. Cellophane is derived from natural sources such as wood and is biodegradable and can be composted. Plastic wrap is created from PVC, and isn’t biodegradable, but it is recyclable.

Now, if you ever need something to store your leftovers in, you’ll know to ask for the plastic wrap, not cellophane.

The cellophane film is transparent, non-toxic and tasteless, resistant to high temperatures and transparent. Because air, oil, bacteria, and water are not easily penetrated through cellophane film, they can be used for food packaging.

As nouns the difference between cellophane and clingfilmis that cellophane is any of a variety of transparent plastic films, especially one made of processed cellulose while clingfilm is thin plastic film used as a wrap for food etc.; Saran Wrap.

As a verb cellophaneis to wrap or package in cellophane.

Welcome to leave your requirements on the website/email, we reply you within 24 hours.

YITO Packaging is the leading provider of cellophane film. We offer a complete one-stop cellophane film solution for sustainable business.