BOPLA Film

BOPLA stands for Polylactic Acid. Made from renewable resources such as corn starch or sugar cane, it's a natural polymer designed to substitute widely used petroleum-based plastics like PET (polyethene terephthalate). In the packaging industry, PLA are often used for plastic bags and food containers.

Our PLA films are industrially compostable plastic films, manufactured from renewable resources.

The PLA film has an excellent transmission rate for moisture, a high natural level of surface tension and a good transparency for UV light.

Biodegradable Materials for Packaging

Material Description

Typical physical performance parameters

| Item | Unit | Test Method | Test Result | |

| Thickness | μm | ASTM D374 | 25 & 35 | |

| Max Width | mm | / | 1020 MM | |

| Roll Length | m | / | 3000 M | |

| MFR | g/10 min(190℃,2.16 KG) | GB/T 3682-2000 | 2~5 | |

| Tensile strength | Width-wise | MPa | GB/T 1040.3-2006 | 60.05 |

| Lengthwise | 63.35 | |||

| Modulus of Elastivity | Width-wise | MPa | GB/T 1040.3-2006 | 163.02 |

| Lengthwise | 185.32 | |||

| Elongation at Break | Width-wise | % | GB/T 1040.3-2006 | 180.07 |

| Lengthwise | 11.39 | |||

| Right Angle Tearing Strength | Width-wise | N/mm | QB/T1130-91 | 106.32 |

| Lengthwise | N/mm | QB/T1130-91 | 103.17 | |

| Density | g/cm³ | GB/ T 1633 | 1.25±0.05 | |

| Appearance | / | Q/32011SSD001-002 | Clear | |

| Degradation rate in 100 days | / | ASTM 6400/EN13432 | 100% | |

| Note:Mechanical properities test conditions are: 1、Test Temperature:23±2℃; 2、Test Hunidity:50±5℃. |

||||

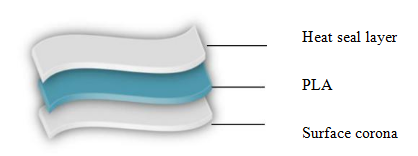

Structure

Advantage

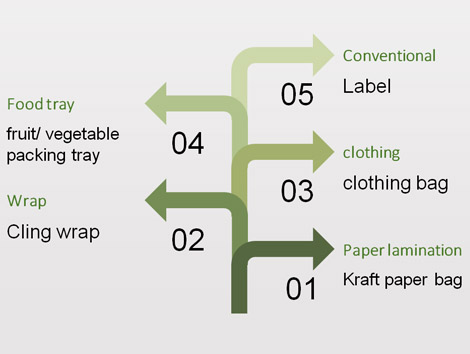

Main Application

PLA is mainly used in the packaging industry for cups, bowls, bottles and straws. Other applications include disposable bags and trash liners as well as compostable agriculture films.

If your businesses currently uses any of the following items and you’re passionate about sustainability and reducing your business’s carbon footprint, then PLA packaging is an excellent option.

What are the benefits of BOPLA products?

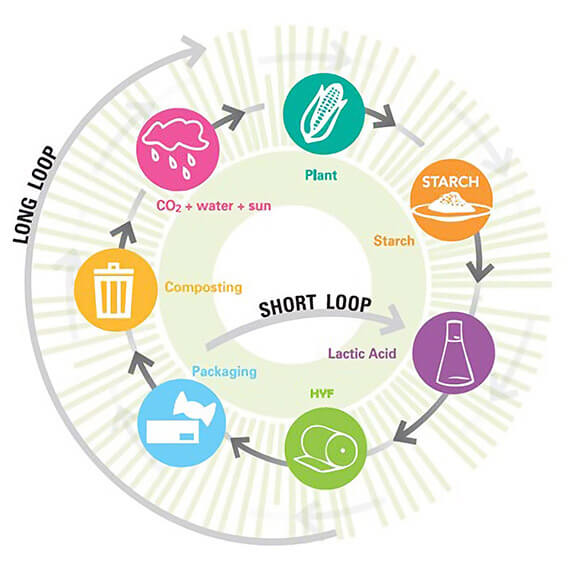

More than 95% of the world’s plastics are created from natural gas or crude oil. Fossil fuel-based plastics are not only hazardous and they’re also a finite resource. And the PLA products present a functional, renewable, and comparable replacement which is made of corn.

PLA is a type of polyester made from fermented plant starch from corn, cassava, maize, sugarcane or sugar beet pulp. The sugar in these renewable materials are fermented and turned into lactic acid, when is then made into polylactic acid, or PLA.

Unlike other plastics, bioplastics dont emit any toxic fumes when they’re incinerated.

PLA is a thermoplastic , it can be solidified and injection-molded into various forms making it a terrific option for food packaging, like food containers.

Food direct contact, good for food packing contaniers.

YITO sustainable packaging films are made of 100% PLA

More compostable and sustainable packaging a key measure to ensure our future. The dependency on crude oil and its impact on future developments made our team to widen its view towards compostable, sustainable packaging.

YITO PLA films are made of PLA resin which Poly-Lactic-Acid is obtained from corn or other starch/sugar sources.

BOPLA Film Supplier

YITO ECO is a eco friendly biodegradable Manufacturers & Suppliers, building circular economy, focus on the biodegradable and compostable products, offering customized biodegradable and compostable products , Competitive Price, welcome to customize!

At YITO-Products, we are about so much more than just the packing film. Don’t get us wrong; we love our products. But we recognize that they are one part of a bigger picture.

Our customers can use our products to help tell their sustainability story, to maximize waste diversion, to make a statement about their values, or sometimes… simply to comply with an ordinance. We want to help them do all of that in the best way possible.

FAQ

PLA, or polylactic acid, is produced from any fermentable sugar. Most PLA is made from corn because corn is one of the cheapest and most available sugars globally. However, sugarcane, tapioca root, cassava, and sugar beet pulp are other options. Like degradable bags, biodegradable are often still plastic bags that have microorganisms added to break down the plastic. Compostable bags are made of natural plant starch, and do not produce any toxic material. Compostable bags break down readily in a composting system through microbial activity to form compost.

PLA requires 65% less energy to produce than traditional, petroleum-based plastics. It also emits 68% fewer greenhouse gases.

The manufacturing process for PLA is also more environmentally friendly than that of traditional plastics made from

finite fossil resources. According to research,

the carbon emissions associated with PLA production

are 80% lower than that of traditional plastic (source).

The food packaging benefits:

They don’t have the same harmful chemical composition as petroleum-based products;

As strong as many conventional plastics;

Freezer-safe;

Direct contact with food;

Non-toxic, carbon-neutral, and 100% renewable;

Made of corn starch, 100% compostable.

PLA does not require special storage conditions. A storage temperature below 30°C is needed in order to minimise the deterioration of the film properties in general. It is advisable to turn over the inventory according to the delivery date (first in - first out).

Products should be stored in clean, dry, ventilation, temperature and appropriate relative humidity of the warehouse, which is away from the heat source of not less than 1m, avoid direct sunlight, not piled up too high storage conditions

The two sides of the package are reinforced with cardboard or foam, and the whole periphery is wrapped with air cushion and wrapped with stretch film;

All around and at the top of the wooden support are sealed with stretch film, and the product certificate is pasted on the outside, indicating the product name, specification, batch number, length, number of joints, production date, factory name, shelf life, etc.Inside and outside the package must be clearly marked the direction of unwinding.