What are Biodegradable Films?

YITO's biodegradable film is a type of plastic film that incorporates additives, typically enzymes, during the manufacturing process, enabling it to decompose under specific conditions. Unlike traditional petroleum based plastic, biodegradable films can be broken down by microorganisms such as bacteria and fungi, minimizing environmental impact.

The decomposition of biodegradable films depends on environmental factors such as temperature, humidity, and microbial activity. Typically, these films can break down into water, carbon dioxide, and biomass within a timeframe ranging from several months to a few years.

Biodegradable Films: Key Raw Materials and Manufacturing Processes

Biodegradable films are often made from biopolymers like polysaccharides (e.g., cellulose, starch), proteins (e.g., soy, whey), and lipids. Starch-based films, for instance, are commonly derived from crops like corn or potatoes.

The manufacturing process involves mixing these biopolymers with plasticizers to enhance flexibility and then forming the film through techniques such as casting or extrusion. Modifications like cross-linking or the addition of nanomaterials may also be employed to improve mechanical properties and barrier performance.

Why are Biodegradable Films Important?

Environmental Sustainability

Biodegradable films are designed to break down into harmless components such as water, carbon dioxide, and biomass, reducing the long-term environmental impact of plastic waste. This makes them a more sustainable choice compared to traditional plastics, which can persist in the environment for centuries.

Waste Reduction

The use of biodegradable films helps to reduce the volume of plastic waste in landfills and oceans. By decomposing naturally, these films minimize the need for waste collection and processing, contributing to a cleaner and healthier planet.

Compostability

Many biodegradable films are compostable, meaning they can be broken down in industrial composting facilities or even in home compost bins. This allows for the recycling of organic waste and the production of nutrient-rich compost, which can be used to improve soil quality.

Renewable Resources

Biodegradable films are often made from renewable resources such as corn starch, sugarcane, or potato starch. This reduces the dependence on fossil fuels, which are finite and contribute to greenhouse gas emissions when extracted and processed.

Functional Properties

Despite being biodegradable, these films can still offer strong barrier properties, flexibility, and durability, making them suitable for a wide range of applications. They can be designed to meet specific requirements for food packaging, agriculture, and other industries.

Positive Brand Image

For businesses, using biodegradable films can enhance their brand image and demonstrate a commitment to environmental responsibility. This can be a significant advantage in a market where consumers are increasingly conscious of the environmental impact of their purchases.

Material Innovations in Biodegradable Films: PLA, Cellophane, and Beyond

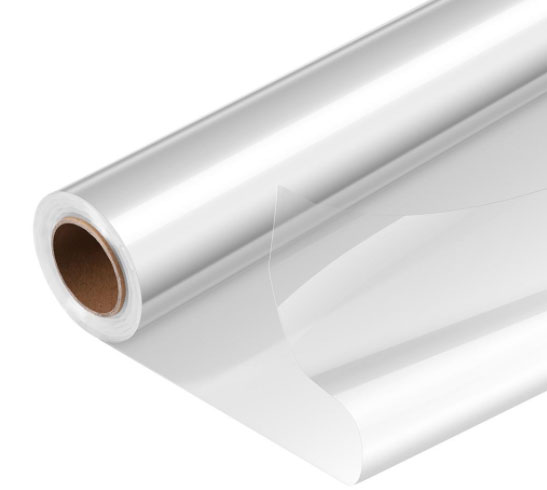

High Quality PLA Film!

YITO Pack's PLA film is a 100% biodegradable and eco-friendly material that decomposes into carbon dioxide and water under specific conditions, promoting plant growth. It has diverse applications, such as biodegradable stretch film for packaging and transportation, and biodegradable mulch film for crop cultivation.

BOPLA Film Wholesale!

BOPLA film, or Biaxially Oriented Biodegradable Polylactic Acid film, is an advanced eco-friendly material that elevates the properties of traditional PLA film to new heights.

This innovative film stands out for its exceptional transparency, which rivals that of conventional petroleum-based plastics, making it ideal for applications where product visibility is crucial.

This innovative film stands out for its exceptional transparency, which rivals that of conventional petroleum-based plastics, making it ideal for applications where product visibility is crucial.

The BOBPLA film's strength is a result of its biaxial orientation process, which not only improves the film's tensile strength but also its puncture and tear resistance, making it more durable and reliable for various packaging needs.

BOBPLA film boasts improved heat resistance compared to standard PLA film.

This characteristic allows it to be used in a wider range of temperature conditions, expanding its applicability in various industries.

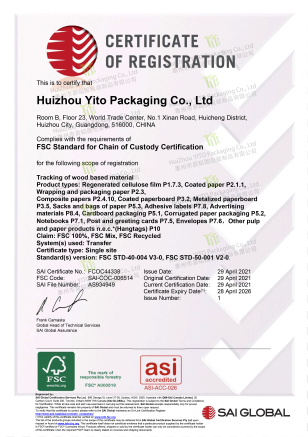

High Quality Custom Cellulose Film

Cellulose is a natural, biodegradable polymer that is derived from plant cellulose fibers, making it an eco-friendly material with a wide range of applications. It is known for its strength, versatility, and renewability, as it can be sourced from various plant materials such as wood pulp, cotton, and hemp.

Cellulose is not only a key component in the production of paper and textiles but also finds use in the creation of sustainable packaging materials like cellophane film. Its inherent properties, such as being fully biodegradable and compostable, make it an attractive alternative to petroleum-based plastics.

As demand for eco-friendly materials grows, biodegradable membrane film wholesale suppliers are increasingly offering cellulose-based solutions to meet industrial needs for scalable, sustainable packaging.

Custom Material & Type as Your Wish

How Biodegradable Films Are Used: Key Applications in Modern Industry

Biodegradable film packaging finds extensive use across various industries, with key applications in the following categories.

Food Packaging

Biodegradable films are widely used for wrapping perishable foods, snacks, and single-use items, like compostable cling wrap, cigar cellophane sleeves, biodegradable cling film and greeting card sleeves. They provide an eco-friendly alternative to traditional plastics, offering strong barrier properties while being compostable. These films help extend the shelf life of food products and reduce plastic waste. Cellulose flow pack film wholesalers, for instance, supply high-performance compostable films specifically designed for automated packaging systems, making them ideal for food manufacturers seeking sustainable flow wrap solutions.

Logistics and Transportation

In logistics, wholesale biodegradable films are used for packaging and protecting goods during transportation and storage. They offer durability and flexibility, ensuring that products remain intact while reducing environmental impact. These films are particularly beneficial for industries with high packaging waste.

Agricultural and Horticultural Use

Biodegradable films are also extensively used in agriculture as mulch films and seeding strips, such as biodegradable mulch film. These films decompose naturally after use, reducing the need for manual removal and improving soil health. They support sustainable farming practices and minimize plastic pollution in agricultural environments.

A Biodegradable Films Packaging Solution Supplier!

FAQ

What makes PLA special is the possibility to recover it in a composting plant. This means a reduction in the consumption of fossil fuels and petroleum derivatives, and therefore a lower environmental impact.

This feature makes it possible to close the circle, returning the composted PLA to the manufacturer in the form of compost to be used again as fertiliser in their corn plantations.

Due to its unique process, PLA films are exceptionally heat resistant. With little or no dimensional change with processing temperatures of 60°C (and less than 5% dimensional change even at 100°C for 5 minutes).

PLA is a thermoplastic , it can be solidified and injection-molded into various forms making it a terrific option for food packaging, like food containers.

Unlike other plastics, bioplastics dont emit any toxic fumes when they’re incinerated.